ø22 Smart RFID Reader

KW2D series smart RFID increases tracking, security, access levels, and productivity of applications. Built for easy integration into industrial systems, this RFID device lets OEM and end users implement secure equipment identification, access control, and traceability.

The built-in Ethernet port that facilitates quick connectivity to host devices like PLCs and HMIs using Modbus TCP. A built-in LED and auxiliary buzzer provide feedback on operation status. KW2D readers operate at standard 13.56MHz high frequency, providing a reading distance of up to 15mm depending on the tag style.

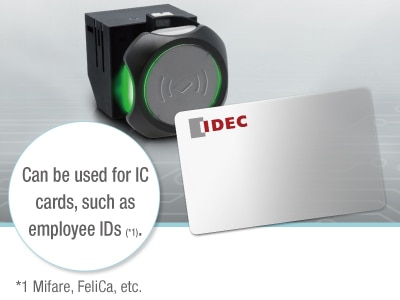

KW2D series supports 3rd party RFID tags if the tags are operated at 13.56 MHz and rated Type A, Type F or Type V standard. Although KW2D works with various RFID tag formats, IDEC-supplied color-coded key fob or card-style tags include enhanced encryption compared with other tag types.

Key Features:

VIDEO

Compact and smart design ideal

for factory automation environments

Mounts on ø22mm panel cut-out

Front unit:

□43.6 × 43.6mm

Panel front height: 9.0mm

Back unit:

□40.0 × 40.0mm

Depth: 48.5mm

Holder feature available

for mounting RFID tags

5 types are available (sold separately)

IP65/67-rated to protect

from washdowns and oil spills.

Designed to work on metal surfaces

often used at factory automation sites.

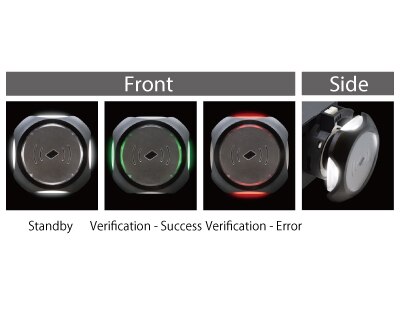

Equipped with an LED easily visible from the side and an auxiliary buzzer, the RFID reader enables visible and audible feedback on operation status.

Can be controlled from a host device (such as a touch panel or PLC).

An Ethernet port enhances connection compatibility with host devices

• Supported protocol: Modbus TCP (server)

* EtherNet/IP and CC-LINK IE FB will be supported soon.

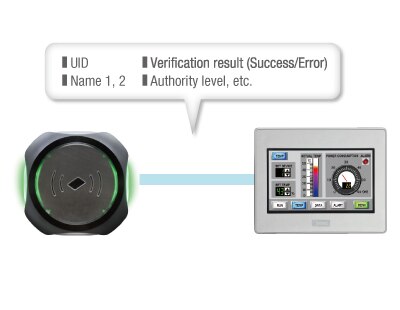

With a verification function inside, the verified result can be communicated to the host device as data.

* If the verification function is not used, a communication error will occur if the result is not sent back to the RFID main unit.

Manage user authority

for machines and devices

BEFORE

Anyone can operate the machines.

AFTER

Inadvertent operation and setting changes are prevented, reducing equipment malfunctions and failures.

Mount the RFID reader on the operation panel of a machine and register the workers in the RFID reader. ID cards can then be used to authenticate each worker.

Track entry/exit at work areas

BEFORE

Do not know if workers are left inside.

AFTER

By recording entry/exit logs, workers can be prevented from being trapped or left behind in a work area.

By recording entry/exit logs, workers can be prevented from being trapped or left behind in a work area.

Manage inspection history

BEFORE

Inspection reports were written by hand.

AFTER

After inspection work, emoyeple ID cards are read and data is recorded.

Inspection details are recorded as electronic data and linked to worker data. The time and work details are recorded on a touch panel or PLC to ensure reliable traceability.

By connecting with devices such as touch panels and PLCs, the RFID reader can be used for wide variety of applications.

Downloads

Catalogs & Brochures

Manuals

Approvals and Standards

Downloads

Catalogs & Brochures

Manuals

Approvals and Standards

RFID Configurator Tool

- KW RFID Configurator

- EDS File (EtherNet/IP)

- CSP File (CC-Link IE Field Basic)