Development of Eco-Friendly Products | |

Basic ConceptSince establishing our product development policy in 1978, the basic development concept of the IDEC Group has been to achieve the optimal control based on the “saving.” With SAVE ALL set as our slogan in 1982, we have committed ourselves to introduce our customers to the “saving” concepts, which includes energy-saving, space-saving, maintenance-saving, and resource-saving. Based on the tendency of the reduction of the environmental burden and the protection of the global environment by the recent social status, we have announced the concept of developing eco-friendly products and have established the procedure in 2017. In 2022, we have reviewed the process of developing products and revised the process to be more eco-friendly. We evaluate the degree of environmental consideration of product development based on IDEC's own standards such as energy efficiency improvement, resource saving, space saving, and a longer product life. The products with high consideration of saving are certified as an "enhanced eco-friendly product". As one of the medium-term targets by FY2025, we have set a target to make eco-friendly products represent 60% or more of all new products launched since FY2020 on a cumulative basis. Not only designing eco-friendly product, we have also addressed to reduce CO2 emissions in the process of manufacturing, transporting, and packing products. | |

Environmental Label (Eco-mark) | |

| We have created am original eco-mark based on our basic spirit of "SAVE ALL". The mark is stamped on the leaflet of products that are certified as "enhanced eco-friendly products" to appeal to our customers. *in compliance with ISO/JIS Q 14021 (self-declared environmental claims: typeII) |

Evaluation Items for Eco-Friendly Products (excerpt) | |

| ・Energy-saving (high efficiency) | Energy-saving design of products |

| ・Resource-saving (materials) | Reduce materials used |

| ・Resource-saving (package, packing materials) | Reduce packing materials, paperless, unlabeled |

| ・Space-saving, weight-saving | Reduce size and weight compared to existing products |

| ・Reduce man-hours | Consider for improving user's workability |

| ・Energy-saving of production facilities | Shorten production process |

| ・Adopt eco-friendly materials (parts) | Apply to component of parts, packing materials, and transporting materials |

| ・Ease of product disassembly | non-use of adhesive agent, reduce screws |

| ・longer operating life | Adopt longer operating parts, easy maintenance |

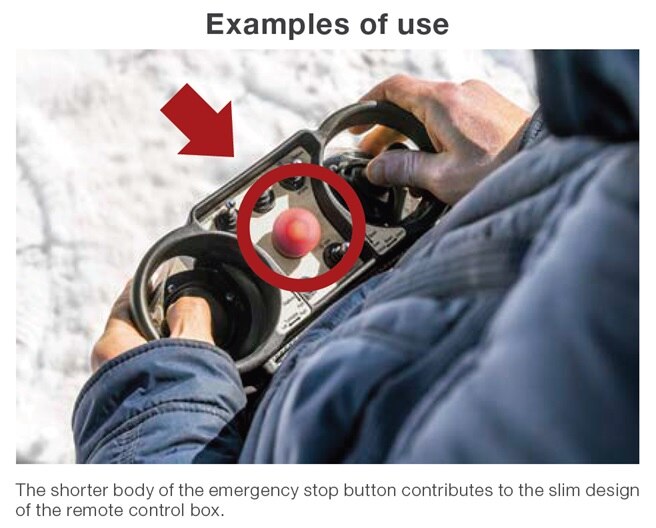

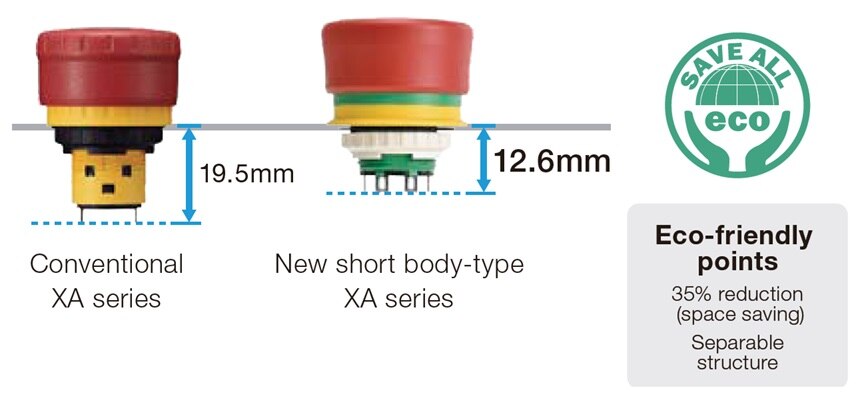

Examples of Eco-Friendly ProductsEmergency-stop switches "XA series"We offer a lineup of switches that are compliant with the ISO 13850:2015 (JIS B9703:2019) safety standard, including illuminator-type switches for identifying active/inactive emergency stop devices, and types equipped with monitor contacts. These emergency-stop switches adopt the third-generation safety potential structure, and have obtained Type 4X (UL certification) for outdoor use. These switches are used as emergency stop devices that operators can operate manually when they sense danger at production sites, or when they sense the possibility of abnormalities or damage to machinery or equipment. In terms of environmental considerations, these products have been developed with features such as a shorter body than conventional models, and consideration for product disposal. |  | ||||

Eco-friendly points①Space saving ②Ease of product disassembly ③Adoption of eco-friendly material |  | ||||