Realization of the Circulating Society

■TOC■ (Click the following each content to jump)

Basic Concept |

Initiatives for non-use of plastic bottles

In 2019, we have started the campaigns to stop selling plastic bottled beverages in vending machines at its major bases and encourages employees to use their own bottles and bring back plastic bottle taken from outside of the head office. Currently, the initiative has been prevailed not only to head office, but also major business bases.

Before "no plastic bottle challenge", approximately 60,000 plastic bottles were consumed at the head office. Only beverages of cans, glass bottles, and paper containers are sold now, and we realized the zero consumption of plastic bottles.

IDEC also participates in the "Plastic Smart" campaign promoted by the Ministry of the Environment and displays posters to raise awareness of the issue of marine plastic waste.

Packing wraps (left) were replaced to reusable packing bands and folding containers (right), which contributes to the reduction of not only packing wraps and cardboard, but also man-hours.

Reduction of plastic bags used at manufacturing bases (Suzhou, China)

IDEC IZUMI SUZHOU (China) has addressed the initiative to reduce the amount of non-reusable plastic bags conventionally used at manufacturing bases and for shipping by using plastic bags, reusable soft trays and foldable containers since August 2022. As a result, a total of 1.598t of plastic bags use was reduced by the end of March 2024.

<Before improvement>

<After improvement>

Introduction of the garbage disposer at cafeteria (Head office, Japan)The garbage disposer which decomposes garbage and water into carbon dioxide and a purification equipment using ozone were introduced to the cafeteria of the head office in February 2022. The purification equipment treats the oil contained in the wastewater, which is expected that the environmental impact of domestic wastewater will be reduced. Approximate eight ton of inedible parts and garbage have been discharged annually from the cafeteria of the head office. By introducing the equipment, it is expected to reduce them to almost "ZERO". In addition, chopsticks used at the cafeteria were replaced from disposable ones to reusable ones, which leads to the reduction of the wastes of disposable chopsticks.

| |

Reduction of food waste with smart cafeterias (Suzhou, China) | |

| The "Smart Cafeteria" introduced at IDEC Izumi Suzhou in May 2023 enables each employee to take the amount of food they want in a buffet format. Depending on the amount of food they take, the weight of the food, meal cost, and remaining balance are displayed on the front panel, and the payment is completed automatically. Since the introduction of the smart cafeteria, not only has the amount of leftover food been reduced by 52% compared to the average for 2022, but waiting time for food to be served has also been shortened and the costs saved have been giving back to employee meals. |  |

Green Purchasing

Basic Concept

IDEC established "Green Purchasing Procedure" for the purpose of promoting the purchase of eco-friendly stationery, office supplies and instruments in 2018. The procedure defines the purchase standards per item such as copy paper, stationery, office furniture based on the Law Concerning the Promotion of the Survey of the Eco-friendly goods and Services by the States and other Entities (Green Purchasing Law) established by the Ministry of the Environment.

By prioritizing the purchase of products in compliance with the Green Purchasing Law and the products with over a certain rate of pulps made of recycled paper and plastics, we aim to form a circular society by sustainable development.

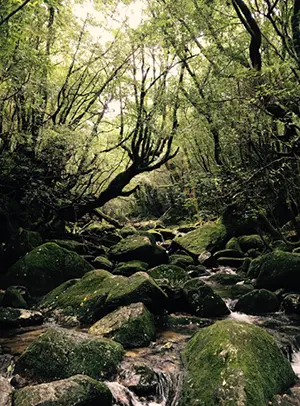

Use of FSC® certified paper (Japan)

FSC® certification system (Forest certification system) is an international certification system that uses strict standards to assess whether forests are managed in an eco-friendly manner to protect the forest environment and whether wood produced from well-managed forests is used as raw material. It is operated by FSC®, Forest Stewardship Council. The notice of the general meeting of shareholders is printed on FSC® certified paper.

Use of vegetable oil ink (Global)

Vegetable oil inks are inks made from plant-derived oils such as recyclable soybean oil, flaxseed oil, tung oil, coconut oil, palm oil, and recycled plant-derived oils from waste edible oils.

Vegetable oil inks are used to print the notice of the annual general meeting.

Provide rainforest alliance certified coffee (Head office)

The Rainforest Alliance is an international non-profit organization dedicated to the conservation of biodiversity and the promotion of the rights and well-being of workers, their families and local residents. The cafeteria of IDEC's head office offers free drinks, and serve coffee to our employees using coffee beans of farms which meet sustainability standards and certified by Rainforest Alliance.