Quality Management |

Implementation Structure

Quality Assurance System

The IDEC Group has established the Quality Management Committee as a system to promote the QMS (quality management system), identify and analyze quality status and problems, and implement improvement initiatives. In addition, each functional department is engaged in continuous improvement activities through the PDCA cycle on a daily basis. Furthermore, for the purpose of operating the quality assurance system of the entire IDEC Group in an effective and comprehensive manner, we are developing the IGQMS (IDEC group global quality management system) to strengthen quality governance by clarifying responsibilities and authority of each area and defining management items common to the IDEC Group. We are fully committed to the continuous development of "Quality IDEC".

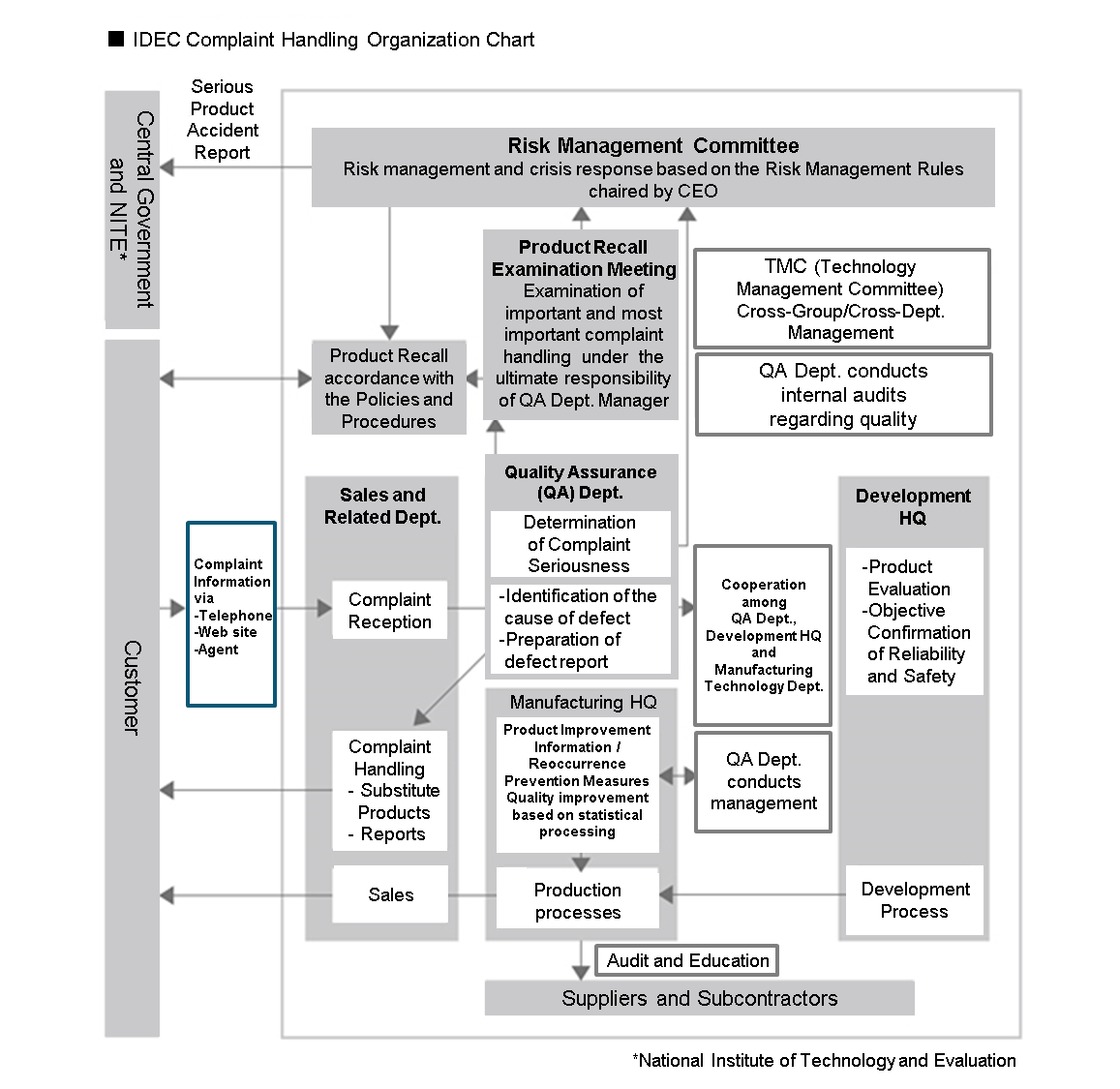

Complaint Handling System

The IDEC Group has a system where departments involved in quality management and quality assurance cooperate closely through effective communication to resolve customer complaints quickly and efficiently, while also ensuring the prevention of recurrence. A new complaint management system introduced in 2024 promotes the digital transformation of this workflow, enhancing customer satisfaction through faster response times and utilizing data as assets for recurrence prevention and quality improvement.

ISO 9001 Certification Acquisition Status

IDEC CORPORATION (ISO 9001:2015)

IDEC FACTORY SOLUTIONS CORPORATION(ISO 9001:2015)

IDEC AUTO-ID SOLUTIONS CORPORATION(ISO 9001:2015)

APEM SAS (ISO 9001:2015)

APEM Components Ltd (ISO 9001:2015)

MEC ApS (ISO 9001:2015)

SACEMA (ISO 9001:2015)

SAMELEC (ISO 9001:2015)

APEM, Inc. (ISO 9001:2015)

IDEC ASIA (THAILAND) CO., LTD.(ISO 9001:2015)

IDEC IZUMI SUZHOU CO., LTD. (GB/T 19001-2016 idt ISO 9001:2015)

IDEC IZUMI TAIWAN CORPORATION (ISO 9001:2015)

| Organization Name | Certification Body | Certification No. | Last renewal date (Registration date) | Expiration Date |

IDEC CORPORATION | SGS Japan | JP22/063231 | (AUG/11/1995) | SEP/30/2027 |

| IDEC FACTORY SOLUTIONS CORPORATION | Intertek Certification Limited | 13729-A | (DEC/8/2006) | APR/16/2027 |

| IDEC AUTO-ID SOLUTIONS CORPORATION | Intertek Certification Limited | 11210 | (SEP/29/2006) | JUL/5/2028 |

■Other Countries /Areas■

| Country / Area | Organization Name | Certification Body | Certification No. | Last renewal date (Registration date) | Expiration Date |

| France | APEM SAS | AFNOR Certification | No1992/776.13 | NOV/14/2025 | NOV/13/2028 |

| UK | APEM Components Ltd | BSI | FM67874 | JUL/1/2025 | JUN/30/2028 |

| Denmark | MEC ApS | Bureau Veritas Certification | DK017289 | (MAR/25/2015) | OCT/14/2026 |

| Tunisia | SACEMA | TÜV Rheinland Cert GmbH | 01 100 2315 611 | OCT/30/2023 | OCT/29/2026 |

| Tunisia | SAMELEC | TÜV Rheinland Cert GmbH | 01 100 2315 612 | OCT/30/2023 | OCT/29/2026 |

| US | APEM, Inc. | TUV NORD CERT GmbH | 44 100 20560015 | MAR/15/2025 | MAR/14/2028 |

| Thailand | IDEC ASIA (THAILAND) CO., LTD. | Japan Quality Assurance | JQA-QMA14888 | OCT/4/2025 | OCT/3/2028 |

| China | IDEC IZUMI SUZHOU CO., LTD. | WIT Assessment | 15/24Q5240R70 | FEB/28/2024 | AUG/1/2027 |

| Taiwan | IDEC IZUMI TAIWAN CORPORATION | ARES International Certification Co.,Ltd | ARES/TW/I1909054Q | SEP/12/2025 | SEP/11/2028 |

To improve the quality level and awareness of quality throughout the company, we continuously provide systematic quality control training with a curriculum for each level of employees as part of our systematic quality education. Basically, quality knowledge should be understood utilized in their own work not only by employees in charge of quality control, but also by a wide variety of employees involved in the manufacturing process. From this perspective, in order to improve the ability of problem-solving and improvement of the entire organization, we conduct training to learn the basic quality control concepts and methods of statistically analyzing data, etc. We also encourage all employees to acquire a quality control certification* so that we can visualize the level of proficiency of each employee. The quality control concepts and statistical methods acquired through these quality education programs are put into practice in actual operations and in QC circles, leading to quality improvement and continuous improvement.

*Quality Control Certificate (QC Certificate) is an objective evaluation of knowledge of quality control through a writing test in Japan, which certifies the level of knowledge of quality control based on pre-determined standards.

Quality Management and Quality Control Examination®

Number of grade holders of the Quality Management and Quality Control Examination®: 639

(Employees and associate employees of IDEC and its subsidiaries as of March 2025)

| Grade 1 | Grade Pre-1 | Grade 2 | Grade 3 | Grade 4 | Total | ||

|---|---|---|---|---|---|---|---|

| Number of holders | 2 | 7 | 67 | 413 | 150 | 639 | |

* The Quality Management and Quality Control Examination® is a registered trademark of the Japanese Standards Association.

This content is not endorsed, recommended, or reviewed by the Japanese Standards Association.

QC Circle Activities

As a part of our quality control activities, employees who work on the frontline of their workplaces conduct ongoing QC Circle activities in each site geared to improving products and work, enhancing the skills of members, creating workplaces full of vitality and so on. Also, we stage the IDEC QC Circle Convention, an annual group convention. At this convention, selected teams from each business office present and share their initiatives and achievements as activity examples; awards are presented to the circles that conduct outstanding activities; and circle activities are vitalized with a view to realizing further improvements in the workplace.

IDEC QC Circle Convention (November 2025)

IDEC QC Circle Convention (November 2025)

Company-wide Quality Conference

The IDEC Group has production sites in 10 countries. To strengthen cooperation between domestic and overseas production sites and enhance quality on the global base, the Company-wide Quality Conference has been held. Through this conference, we aim to improve awareness of quality and strengthen cooperation among each site, which leads to the improvement of the quality management system of the entire IDEC Group. This conference brings together site and quality managers from production sites in each country to strengthen cooperation through sharing and discussing quality issues and improvement measures; moreover, managers in charge of development, logistics, purchasing and sales also cooperate in a company-wide effort to enhance quality.

Company-wide Quality Conference (September 2023)

Company-wide Quality Conference (September 2023)