- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Automotive

- Solutions

- Explosion-Proof Lighting

- Explosion-Proof Lighting

- Robot Collaboration

- Robot Collaboration

- Dual-Action Interlocking

- Dual-Action Interlocking

- Smart Safety Gates

- Smart Safety Gates

- Large Inductors

- Large Inductors

- Small Equipment Safety

- Small Equipment Safety

- Solutions

- Automotive

- Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Robotics

- Solutions

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Safety Switches

- Robot Safety Switches

- Robot Warning System

- Robot Warning System

- Solutions

- Robotics

- Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Special Vehicles

- Solutions

- Illuminated Switches

- Illuminated Switches

- Construction Site Safety

- Construction Site Safety

- LED Pilot Light

- LED Pilot Light

- Rugged Switch

- Rugged Switch

- Auto Machinery

- Auto Machinery

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Special Vehicles

- Control Panel

- Solutions

- Solutions

- Control Panel

Wearable Code Reader | India

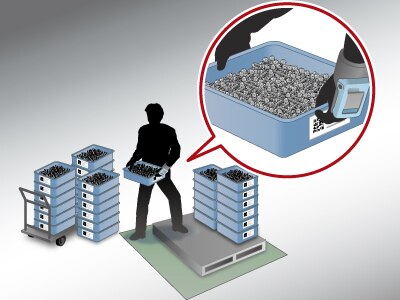

Eliminate the risk of accident when performing work with one hand holding a code reader

Frequent multi-tasking work is a cause of production line errors and accidents

When sorting products shipping to different destinations, two codes, of which are cases full of products and a pallet prepared by each shipping destination, are read and the products are loaded to the corresponding pallet taken out from the cases. Although workers can switch out cases while reading, one by one, each code of the cases that have been gathered together and brought in for sorting, cases with a large number of products are heavy, resulting in a constant risk of cases falling.

Handheld code readers are currently used for these operations, workers must put the code reader back into the hip holder after reading a code before firmly grasping a case with two hands to switch it out, such that the procedure requires two separate actions.

However, as this method requires workers to pull out the code reader each time they switch out a case, it is not only inefficient, it can also invite dangerous "multi-tasking" if a worker tries to switch out a case while still holding the code reader.

This multi-tasking work increases the risk of accident due to failure to properly grasp the case and dropping it, and similar causes. In the worst cases, this can result in worker injury, or lost time due to having to repair the damaged product.

There are certainly many plant line supervisors who have the concern, "No matter how many times I caution my workers, it is impossible to completely eliminate such multi-tasking work."

Use of a wearable code reader is a simple way to eliminate the risk of accident

In actuality, there is a simple way to eliminate multi-tasking, a problem not readily resolved even by constantly calling it to the attention of workers. The solution to this is the use of wearable code readers. IDEC recommends introducing our WIT-220-NR Wearable Terminal that can be secured to the wrist or back of the hand as a perfect solution that both optimizes work efficiency and ensures safety. The WIT-220-NR is about the size of a small smartphone and weighs just 94 grams. You can use the attachment to secure the code reader to your wrist or back of your hand and hold it up to the code to read the information. This frees up use of your hands and eliminates the risk of multi-tasking and dropping a box. Moreover, use of our wearable code reader also cuts the labor time lost returning the code reader to the holder in order to make for smoother and safer shipping preparation work.

In actuality, there is a simple way to eliminate multi-tasking, a problem not readily resolved even by constantly calling it to the attention of workers. The solution to this is the use of wearable code readers. IDEC recommends introducing our WIT-220-NR Wearable Terminal that can be secured to the wrist or back of the hand as a perfect solution that both optimizes work efficiency and ensures safety. The WIT-220-NR is about the size of a small smartphone and weighs just 94 grams. You can use the attachment to secure the code reader to your wrist or back of your hand and hold it up to the code to read the information. This frees up use of your hands and eliminates the risk of multi-tasking and dropping a box. Moreover, use of our wearable code reader also cuts the labor time lost returning the code reader to the holder in order to make for smoother and safer shipping preparation work.

IDEC's vast storehouse of know-how and ample lineup contributes to optimizing your production line work efficiency and improving safety.

IDEC provides support for improvements in a wide variety of industries with unique case-by-case solutions that include not only the WIT-220-NR Wearable Terminal but also conducting flow management using beacons and similar useful solutions. IDEC's strength lies in this long-term accumulation of know-how and wide-ranging product lineup, contact us if you are interested in optimizing your operations.