- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Automotive

- Solutions

- Explosion-Proof Lighting

- Explosion-Proof Lighting

- Robot Collaboration

- Robot Collaboration

- Dual-Action Interlocking

- Dual-Action Interlocking

- Smart Safety Gates

- Smart Safety Gates

- Large Inductors

- Large Inductors

- Small Equipment Safety

- Small Equipment Safety

- Solutions

- Automotive

- Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Robotics

- Solutions

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Safety Switches

- Robot Safety Switches

- Robot Warning System

- Robot Warning System

- Solutions

- Robotics

- Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Special Vehicles

- Solutions

- Illuminated Switches

- Illuminated Switches

- Construction Site Safety

- Construction Site Safety

- LED Pilot Light

- LED Pilot Light

- Rugged Switch

- Rugged Switch

- Auto Machinery

- Auto Machinery

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Special Vehicles

- Control Panel

- Solutions

- Solutions

- Control Panel

Smart EMO Switches | India

How can major losses be avoided from damage on EMO switches of semiconductor manufacturing machines?

Risks of major losses from EMO switch damage

In semiconductor manufacturing, the most important challenge is how to keep the productivity of factories high while keeping machines operating. There are processes where dangerous solvents and chemicals are used and if power supply is cut due to emergency stop switches that shut down the power to machines, a dangerous secondary condition such as gas leak may occur. Thus, SEMI, the semiconductor industry safety standards, requires EMO switches be installed to close only the load areas that created dangerous conditions and to keep the movement of other safety-related equipment. However, the mechanical structure of conventional EMO switches poses risks that circuits may not be interrupted even if the switches are pressed, if the switches are damaged due to excessive impact. Some of semiconductor manufacturing machine manufacturers would mostly likely have the need of improving safety of machines by minimizing such risks.

EMO switches with reliable safety mechanisms to securely shut off only the circuit under dangerous conditions

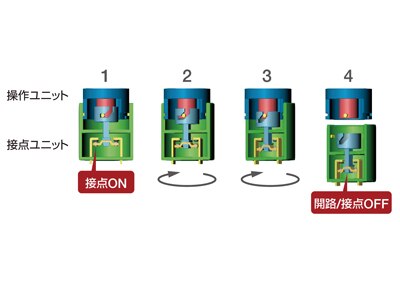

Being able to interrupt only the part of the circuit that caused dangerous conditions in an emergency situation is crucial to the credibility of semiconductor manufacturing machines. What IDEC has to offer for semiconductor manufacturing machine manufacturers who need to design safe machines is the third generation EMO Stiches, the XW series. The XW series are equipped with two safety structures: Reverse Energy Structure and Safe Break Action. Even if switches are damaged due to excessive force or impact, or even if the contact block is detached from the operator unit due to improper installation, NC contact remains closed mechanically (contacts OFF) to shut off the circuit of the operation part that caused dangerous conditions. Thus, even if EMO switch operations fail, the problem circuit can be securely shut off, which ensures that losses in the factory do not expand. The various product line-up of switch guards and stickers are available for EMO switches of the XW series. Many accessories to prevent unintentional operation at normal occasions are available, too.

A wide variety of switches for flexible design

Semiconductor manufacturing machines are not only required to secure safety, but also need to meet with a growing demand for downsizing. IDEC has the o16mm XA series in addition to the o22mm XW Series for semiconductor manufacturing machine makers who opt for further downsizing. Either series have variations in button shapes and sizes and can satisfy designers’ requests for smaller machines and ease of use. SEMI S2-compliant switch guards are available, too, for various purposes. Let IDEC help you ensure safety as IDEC switches and other products are always updated to meet changes in the standards such as ISO and SEMI.