- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Automotive

- Solutions

- Explosion-Proof Lighting

- Explosion-Proof Lighting

- Robot Collaboration

- Robot Collaboration

- Dual-Action Interlocking

- Dual-Action Interlocking

- Smart Safety Gates

- Smart Safety Gates

- Large Inductors

- Large Inductors

- Small Equipment Safety

- Small Equipment Safety

- Solutions

- Automotive

- Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Flat LED Lighting

- Flat LED Lighting

- Smart Relays

- Smart Relays

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Robotics

- Solutions

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Safety Switches

- Robot Safety Switches

- Robot Warning System

- Robot Warning System

- Solutions

- Robotics

- Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Production Line Safety

- Production Line Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Waterproof Switches

- Waterproof Switches

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Smart Controllers

- Smart Controllers

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- Easy Switch Replacements

- Easy Switch Replacements

- Special Vehicles

- Solutions

- Illuminated Switches

- Illuminated Switches

- Construction Site Safety

- Construction Site Safety

- LED Pilot Light

- LED Pilot Light

- Rugged Switch

- Rugged Switch

- Auto Machinery

- Auto Machinery

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Special Vehicles

- Control Panel

- Solutions

- Solutions

- Control Panel

Traceable Systems | India

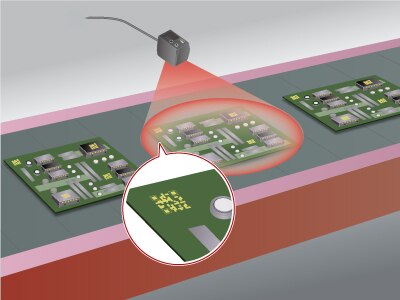

Accurate and simple code reading of direct parts marking

For the problem of additional time and effort and costs of code reader adjustment

A recently common method at production sites where traceability is a major concern is to perform "Direct Parts Marking" (DPM) in which a code is directly marked on the parts themselves. DPM of parts that are too small for affixing a label consists of inscribing the part with the code, allowing it to be used for a wide variety of industries such as electronic parts and medical equipment. Many semiconductor manufacturers probably have already introduced DPM or are probably currently studying its introduction.

Various highly flammable gases such as hydrogen, propane and arsine are used in manufacturing semiconductors. A conventionally used measure to prevent explosion is to eliminate arc generation, which is one aspect of gas discharge, when equipment is charged with nitrogen. Although some may believe that this is a sufficient safety measure, measures such as these cannot be said to thoroughly prevent explosion. To understand why, it is necessary to realize that even if using the conventional method of charging with gas, there is still a possibility of an explosive atmosphere being created if a machine charged with nitrogen suffers a malfunction, such that the risk of explosion is not completely eliminated. The question then is, what are proper explosion-proof measures to apply to semiconductor manufacturing sites?